I reckon your toilet’s inner workings don’t cross your mind much, especially when it is working flawlessly. However, since the flushing power is a fundamental consideration when buying a toilet, how does a canister flush valve vs flapper compare?

A canister flush valve is mainly found in modern toilets and features a cylindrical or canister-shaped mechanism. It’s more efficient and durable than flappers. On the other hand, flappers are found primarily in older toilets and feature a rubber or plastic valve.

The choice between a canister flush valve and a flapper can significantly impact the performance, water efficiency, and maintenance of your toilet. Therefore, let’s dig deeper into these components to help you decide the one that will suit you best.

Canister Flush Valve Vs Flapper Defined!

Before we compare these components, below is a definition of the canister flush valve and flapper.

1. Flapper Flush Valves

A flapper flush valve, a plastic or rubber valve covering the flush valve, controls the water release from the toilet tank into the bowl when you flush.

Here’s how a flapper works:

Pressing the toilet’s flush handle or lever lifts your flapper valve. This, in turn, exposes the flush valve opening, facilitating water flow to the bowl.This sudden water rush creates the force needed to clean the bowl.

The flapper returns to its place when the toilet tank is empty, covering the flush valve opening. This re-seals the tank, thus preventing further water flow.

Pros and Cons of Flapper Flush Valves

Pros

- Simplicity: Flapper-style flush valves are straightforward in operation and design, hence easy to repair and maintain.

- Cost-Effective: Toilets equipped with flapper-style flush valves are generally more affordable.

- Widely Available Replacement Parts: Replacement flappers and other components for flapper-style flush valves are widely available at hardware stores and home improvement centers. This accessibility simplifies maintenance and repairs.

- Low Water Pressure Tolerance: Flappers can often work efficiently with low water pressure, making them suitable for areas with less-than-optimal plumbing conditions.

- Proven Technology: Flapper-style flush valves have been used in toilets for many years and have a track record of reliability. Many people are familiar with their operation and trust their performance.

- Minimal Risk of Jamming: Unlike other flush mechanisms with moving parts, flapper-style valves have fewer components that can potentially jam or malfunction.

Cons

- Water Inefficiency: Flappers use more water per flush than modern, water-efficient flush mechanisms.

- Inconsistent Flush Performance: Over time, the rubber flapper can deteriorate, harden, or develop leaks, leading to inconsistent flush performance. Sometimes, it may not completely seal the flush opening, resulting in water wastage or frequent double-flushing.

- Potential for Leaks: Flappers are susceptible to leaks, especially when the rubber flapper becomes worn or damaged. These leaks can lead to a continuous trickle of water into the bowl, wasting water and increasing water bills.

- Maintenance Requirements: Even if flappers have a simple design, you’ll need to replace and maintain it often.

- Limited Water-Saving Options: Flapper flush valves typically do not offer water-saving features like dual-flush options or adjustable flush volumes.

- Noise: Some flapper flush valves can be noisier compared to other flushing mechanisms during operation, leading to a louder flush.

- Limited Features: Flappers lack advanced features and options in more modern flush mechanisms, such as touchless flushing, integrated bidet functions, or customizable flush settings.

- Reduced Flush Power: Some flapper-style flush valves have less flushing power. Therefore, you’ll likely need to flush multiple times to completely clear waste.

2. Canister Flush Valve

A canister flush valve refers to a component found in modern toilet tanks responsible for releasing water from the tank into the toilet bowl to facilitate flushing. It serves a similar function to the traditional flapper valve but operates differently and is designed to be more durable and efficient.

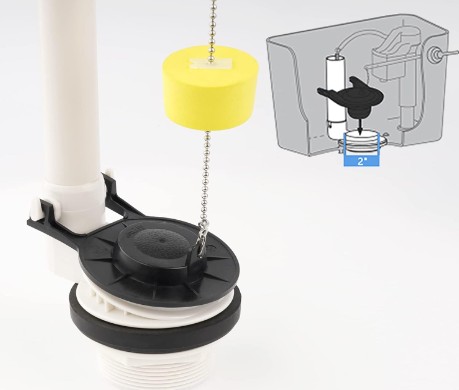

Instead of a rubber flapper, the canister flush valve uses a cylindrical or canister-shaped mechanism that sits at the bottom of the toilet tank. How does it work, though?

The toilet’s flush handle or button lifts the canister valve’s seal when you press it. As the seal lifts, water from the tank flows into the toilet bowl through a larger, more direct opening than traditional flapper valves, allowing for a more powerful and efficient flush.

After flushing, the canister valve drops back down, creating a watertight seal. This design reduces the likelihood of leaks and the amount of water that can evaporate from the tank, thus conserving water over time.

Pros And Cons Of Canister Flush Valves

Pros

- Improved Flush Performance: Canister flush valves can release a larger volume of water into the bowl more quickly than flappers, resulting in better waste removal and less frequent clogging.

- Durability: They are less susceptible to deterioration.

- Consistency: Canister valves perform consistently for longer periods than flapper valves.

- Water Efficiency: Many canister flush valves are designed to be water-efficient. Some have dual flush mechanisms.

- Ease of Maintenance: Canister flush valves are easier to access and maintain than flapper-style valves.

- Reduced Noise: The canister flush valve design minimizes water hammer or slamming sounds, contributing to a quieter bathroom environment.

- Design Flexibility: Canister flush valves are available in various designs and configurations, giving you multiple options. Therefore, you can easily find what fits your style and needs.

- Reduced Risk of Leaks: Canister flush valves are less prone to leaking compared to flapper-style valves. Their design creates a tighter seal, reducing the likelihood of water leakage into the bowl between flushes.

- Enhanced Hygiene: Some canister flush valves have features like touchless flush activation or antimicrobial coatings on the canister surface.

Cons

- Complexity: Canister flush valves are more complex in design than flappers, making them slightly more difficult to repair or replace.

- Cost: Canister flush valves and toilets that use them tend to be more expensive.

- Compatibility Issues: Canister flush valves are not universally compatible with all toilet models.

- Dependence on Water Pressure: Canister flush valves rely on adequate water pressure to perform efficiently.

Canister Flush Valve Vs Flapper: Factors To Consider During Selection

So, we have defined both the canister flush and flapper flush valves and examined their pros and cons. There are a few more things to cover when choosing between these two flushing components.

Consider the following during your selection.

1. Diameter

Canister and flapper flush valves come in different sizes, and the diameter can impact the flush performance and efficiency of a toilet. A flush valve with a longer diameter releases more water into the toilet tank, which translates to a more powerful flush.

Canister flush valves typically have a larger diameter compared to flapper flush valves. The diameters of flush valves often vary depending on the toilet model and manufacturer, but canister flush valves are typically 3 inches or more in diameter.

On the other hand, flapper flush valves are around 2 inches in diameter, like this easy-to-install, quality Toilet Flapper Replacement (View on Amazon).

2. Durability

Canister valves are generally considered more durable than flapper valves because they have fewer moving parts, reducing the chances of wear and tear. In contrast, flapper valves often wear out over time due to the repeated bending and flexing of the rubber or silicone flapper.

Also, canister valves are often made from durable materials like hard plastic or rubber, which are less prone to deterioration, cracking, or warping. For instance, the 3-inch Kohler Toilet Canister Flush Valve (View on Amazon) is made of brass and has a plastic exterior finish.

On the other hand, the rubber or silicone flappers in flapper flush valves can be damaged by cleaning chemicals and water treatments.

3. Maintenance

Canister flush valves generally need less maintenance compared to flapper flush valves since they have fewer moving pieces and a simpler design. However, both types of valves benefit from regular inspections to ensure proper operation and water conservation.

4. Flush Performance

The popularity of canister flush valves lies in their powerful flush performance. They allow a large volume of water to be released into the bowl quickly, creating a strong and efficient flush that clears water and prevents clogs.

In contrast, the flush performance of toilets with flapper flush valves varies depending on the toilet model and the quality of the flapper. Some flapper valves provide adequate flush performance, while others may be less effective.

Flapper flush valves typically release water more slowly and create a less forceful flush than canister valves. Sometimes, you may need to double flush to clear the bowl completely.

5. Water Efficiency

Canister flush valves and flapper flush valves can be designed to be water-efficient. A toilet’s water efficiency lies in its overall design, flush valve components, and additional features like dual-flush options.

When choosing a water-efficient toilet, look for the WaterSense label or check its flush volume to ensure it meets your water conservation goals.

6. Cost

Toilets come in various price points, whether they have canister or flapper flush valves. However, toilets with canister flush valves are slightly more expensive upfront than those with flapper flush valves.

This is because canister valves are often associated with higher-end or more modern toilet designs. Aside from the initial cost, you should consider water savings capabilities and maintenance requirements during selection.

Although buying a canister flush valve toilet will cost you more upfront, you will benefit from long-term savings on water bills and maintenance costs due to their durability and efficiency.

7. Compatibility

Flapper flush valves have an advantage over canister flush valves when it comes to compatibility due to their wider range of universal parts and broader compatibility with various toilet models. Canister flush valves are often more model-specific, which may require you to source replacement parts from the toilet’s manufacturer or find exact matches to ensure compatibility.

8. Existing Plumbing

Retrofitting an existing toilet with a canister flush valve might require more effort and expense compared to simply replacing a flapper.

9. Noise Level

A toilet with a canister flush valve is better if you prefer quiet operation. This is because canister flush valves are generally quieter and deliver a more controlled flushing action than flappers.

Final Remarks on Canister Flush Valve Vs Flapper Flush Valve

Generally, the canister flush valve is a better and modern flushing mechanism than a flapper. However, the choice between them is not a one-size-fits-all decision, as each has advantages and disadvantages. So, consider factors such as water efficiency, cost, ease of maintenance, and personal preference during selection.

Also, Read: